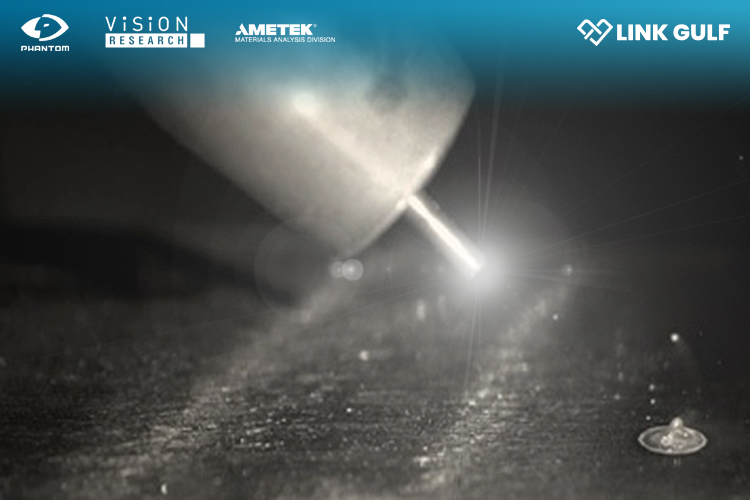

When it comes to ‘A Job Weld Done’ – To optimise welding techniques, engineers and researchers must closely look at what transpires at the site of the weld. It is often a challenge to visualise, however, because these techniques emit blinding light, and the events of interest are extremely short-lived.

Fortunately, an advanced imaging technique called pulse laser illumination — which combines high-speed cameras and pulse lasers — provides researchers with insight on how to improve welding methods. So to understand a Job Weld Done – Here’s how it works.

Observing welding processes allows researchers to analyse how molten metal transitions to a solid, along with the physical processes that influence weld quality like spattering, deformation and cracking. Capturing the details of these small, bright and brief events using a high-speed camera is impossible with standard lighting techniques because of the intense light, leading to over-exposed images. While it may seem counterintuitive, the solution is to direct more light toward the welding site using a laser.

By illuminating the welding site with a high-powered laser. This filters out all the light wavelengths that are not the same as the incident laser. High-speed imaging experts can therefore capture high-quality, high-speed footage of an extremely bright event. Pulse lasers are ideal for this type of illumination. While LED arrays are sometimes used, they are more difficult to set up and usually don’t generate enough power to overcome the intensity of the welding sparks.

Another advantage to using a pulse laser is the fact that lasers can be synchronised with the camera’s frame rate. This synchronisation ensures the camera only records laser pulses when the welding site is properly illuminated. In addition, using a monochromatic laser simplifies the light-filtering process. A crucial component in pulse laser lighting is the optical band-pass filter. This only permits light of the same wavelength as the laser to enter. Scattered light from the welding application is therefore not detected by the camera.

Before digging into how to make use of this advanced lighting technique, it’s important to be aware of the potential hazards of working with high-powered Class IV lasers. These lasers are dangerous, and it’s crucial to make sure you direct the laser toward the field of interest during operation. Personnel operating the equipment should take the necessary precautions. This includes wearing appropriate personal protective gear.

The setup to record a welding application with pulse laser illumination is not complex. First, position the camera as you would a conventional application. Then position the laser. It’s important to ensure the laser is targeting exactly where the welds will occur. Next, with both the camera and laser in place, station the band-pass filter in front of the camera. The filter must be specified to only permit the exact wavelength of light that the laser emits in order to ensure successful image capture.

After the camera, laser and filter are in place, the next trick is to coordinate the camera with the laser. Once the camera is connected to the laser controller, you can adjust the laser’s pulse width, power, frequency and other parameters. Finally, as in typical imaging applications, test the laser and camera settings to ensure the highest quality footage.

Keep in mind that exposure time does not play a major role in dictating the brightness of the footage. Instead, the pulse laser frequency determines the brightness, with higher frequencies providing brighter images.

Phantom high-speed cameras deliver excellent resolution while recording at high frame rates. Another key feature, in-camera signal control, provides an advantage for pulse laser lighting. With in-camera signal control, you can configure each Phantom camera to delay the trigger signal so that it perfectly synchronises with the laser pulse. This feature ensures that both the laser illumination and the exposure time occur simultaneously.

In addition to welding, combining Phantom cameras with pulse laser illumination is useful for other extremely bright and brief applications like ballistics and explosion research.

Contact us today to find out what Phantom High-Speed Cameras can do for you.

Phantom Cameras Website: phantomhighspeed.com