-

It provides improvements in health and safety, as well as environmental impact.It is cost effective when setting up a new lab, with less equipment and space required.

-

The binder content is available more quickly than with modified binders than with traditional methods.The test method is less “operator sensitive” than solvent methods.

-

There is less “hands-on” time required by staff.

-

The success of any new test method has to be measured by its accuracy. The advent of the Sector 14 scheme, and its requirement for independent audit samples, has given additional data on the reproducibility aspects of the test.

-

The north of England area of Aggregate Industries currently operates five binder ignition furnaces (from various manufacturers), and no solvent is used in the area.

-

Data gathered from audit samples taken over the past four years has indicated a good correlation with the more conventional test methods.

-

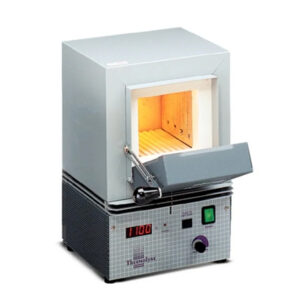

Automatically calculates & uses calibration factors based on both asphalt mixes and dry aggregates

-

Unique automatic input of sample start weight via an optional second external balance eliminates operator error

-

Rapid heat up rates permit the unit to be switched off between test, resulting in reduced power consumption and eliminating the need for a 24-hour timer

-

Customisation of test parameters & ability to save named test setups in a library

-

Permits large sample sizes – up to 4.5kg – to be be tested

-

Independently controlled afterburner significantly reduces furnace emissions

-

Eliminates health & environmental concerns related to use of chlorinated solvents

-

Used by Tarmac, RMC, Lafarge, Aggregate Industries/Bardon Aggregates