Home » Link Gulf – Main Store Page » Robotics » Quadruped Robots » Deep Robotics – X20 Quadruped Robot

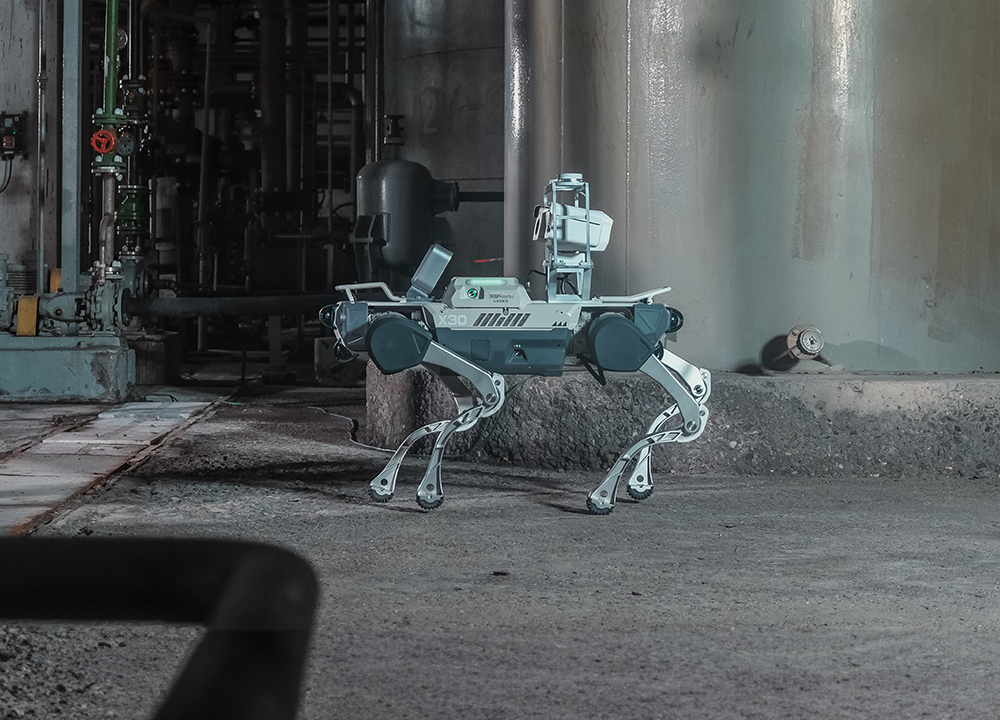

The Deep Robotics X20-Quadruped Robot – Breaking New Boundaries in Quadruped Robotics – The X20 quadruped robot solution is for industrial patrol inspection under extreme working conditions. With industrial-grade water and dust resistance, strong load, and smart perception, users can complete unmanned autonomous inspection with a robot dog in a large environment.

Request a Quote

Prices shown are for the United Arab Emirates only and are excluding VAT @ 5% Local Rate (Unless Otherwise Stated).

Other countries may incur additional import duties – Please Contact Us for further details and pricing for your location.

Deep Robotics X20-Quadruped Robot

Breaking New Boundaries in Quadruped Robotics – The X20 quadruped robot solution is for industrial patrol inspection under extreme working conditions. With industrial-grade water and dust resistance, strong load, and smart perception, users can complete autonomous inspection in a large environment.

Industrial Applications

Pioneering Innovation & Application of Embodied AI – Helping humans complete repetitive and dangerous tasks.

The quadruped robot dog can assist in transforming and upgrading traditional electric power inspection. Featuring DEEP Robotics’ advanced technologies, robotics can help achieve intelligent inspection, operation, and maintenance. This helps digitally transform the development of the electric power industry. The DEEP Robotics quadruped robot also has a string adaptation capability to achieve rapid deployment, high-precision data acquisition, precious inspection, analysis, danger warning, and other efficient intelligent abilities to realize a closed-loop workflow.

The Deep Robotics X20-Quadruped can go into toxic, hypoxia, collapses, and other post-disaster areas for detection rescue missions for firefighters. It can dive deep into severe environments to operate omnidirectional object scouting and toxic gas sensing. This facilitates the transport of rescue materials and equipment to assist in missions.

The quadruped robot dog is capable of Unmanned autonomous inspection in complex terrains of underground cable tunnels. Prevent errors in traditional inspection, and improve the efficiency of monitoring devices’ status; smart detection to unusual situations, reduce inspection cost and improve overall efficiency.

Unmanned patrol surveying in complex environments such as narrow spaces, heavy dust, muddy and slippery roads, multi-pipe cables, and obstacles, can greatly reduce the risk of manual patrol inspection. Quadruped robots can work in all weather which can improve the efficiency and productivity of patrol inspection, and prevent equipment failures ahead of time; Also, Quadruped robots can continuously collect data, go deep into blind spots, and generate data analysis reports to support experts making faster responses to reduce the occurrence of accidents.

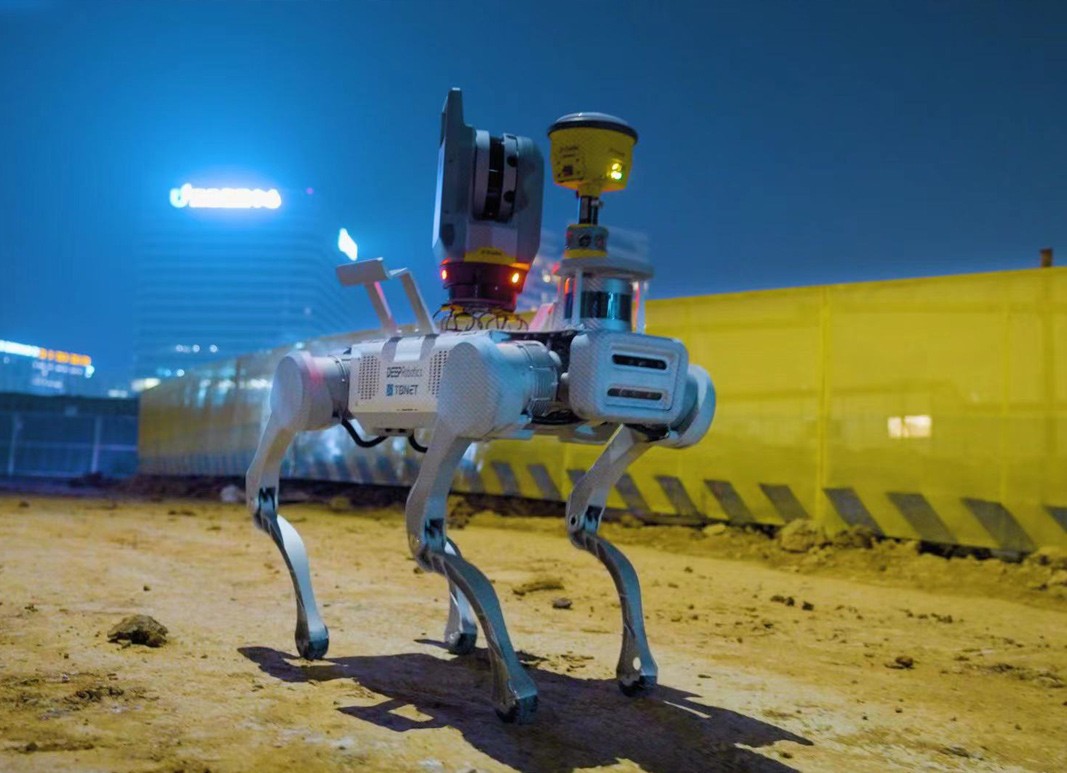

Carry out auxiliary surveying and mapping for complex surveying environments, combine AI intelligent algorithm and its excellent obstacle avoidance function, automatically perform multiple complex and repetitive tasks such as on-site scanning, surveying and mapping, project progress monitoring, etc. according to the task path, and obtain more accurate surveying and mapping results through data processing and analysis, greatly improve efficiency and reduce safety risks.

Provide diversified development support, help users understand the characteristics, performance, and operation methods of robots; help to deeply understand the leading technology and application direction in the industry.

Fully automatic patrol inspections can be carried out in toxic and harmful environments with high temperatures or high pressure to reduce personnel safety threats, reduce labor costs and reduce human error; The intelligent patrol module and technology can be used to collect detailed data and transmit it to the data center for analysis.

| Dimensions | |

| Standing size | 950mm x 470mm x 700mm |

| Weight | 53kg |

| Motion | |

| Endurance | 20kg |

| Slope | ≥ 30° |

| Step/Obstacle’s H | ≥ 20CM |

| Max.Speed | ≥ 4M/S |

| Protection | |

| Ingress protection | IP66 |

| Battery | |

| Endurance | 2-4h |

| Mileage | 15km |

| Communication | |

| Interface | / |

* All parameters are laboratory data, operating in a real environment may have differences.

* The product is subject to the actual delivery, and DEEP Robotics reserves the right of final interpretation.