Home » Entire Product Range » 3D PRODUCTION SOLUTIONS » 3D Printer Accessories » Bambu Lab AMS2 Pro – Automatic Material System

Bambu Lab AMS 2 Pro – AMS, Evolved.

AMS 2 Pro compatibility with A1/A1 mini printers will be added through an OTA update in Q3 2025.

The AMS 2 Pro is compatible with X1/P1 series printers for multi-material printing.

For X1/P1 owners, a switching adapter is needed to power the drying function. Since filament drying lasts long, you rarely need multiple adapters running simultaneously. The optional adapter helps lower the price.

For H2D owners, your H2D can power anyone of the AMS 2 Pro(s) connected for drying, so if you’re not planning to run multiple AMS 2 Pro for drying simultaneously, you won’t need an adapter.

OUT OF STOCK, PRE-ORDER NOW

AED1,765

Prices shown are for the United Arab Emirates only and are excluding VAT @ 5% Local Rate (Unless Otherwise Stated).

Other countries may incur additional import duties – Please Contact Us for further details and pricing for your location.

OUT OF STOCK, PRE-ORDER NOW

Bambu Lab AMS2 Pro – AMS, Evolved.

The Bambu Lab AMS2 Pro compatibility with A1/A1 mini printers will be added through an OTA update in Q3 2025.

The AMS 2 Pro is compatible with X1/P1 series printers for multi-material printing.

For X1/P1 owners, a switching adapter is needed to power the drying function. Since filament drying lasts long, you rarely need multiple adapters running simultaneously. The optional adapter helps lower the price.

For H2D owners, your H2D can power anyone of the AMS 2 Pro(s) connected for drying, so if you’re not planning to run multiple AMS 2 Pro for drying simultaneously, you won’t need an adapter.

X1 Series and P1 Series are compatible with AMS 2 Pro. If only using the automatic filament feeding function, only the 6-pin bus cable, 4-pin bus cable, Filament Buffer/AMS Hub, PTFE Tube and PTFE Tube Coupler are required, and no external power adapter is needed. However, if you need to use the drying function, an external power adapter is required for the AMS 2 Pro.

The powerful Bambu permanent magnet synchronous servo motor accelerates filament feeding by 60% for enhanced efficiency. Saves an average of 10 minutes per 100 filament changes. Saves an average of 10 minutes per 100 filament changes.

Tool-Free Filament Tubes Access – Removing snapped filament from the first-gen AMS requires extracting all spools and disassembling the shell with two screws, taking 3-5 minutes. In contrast, the AMS 2 Pro offers direct, tool-free access to filament tubes from the top.

Ceramic Inlet – Ceramic filament inlets with a Vickers hardness of 1200 significantly enhance durability.

Compatible With All Bambu Lab Printers – The AMS 2 pro is compatible with all Bambu Lab products

| Body | Dimensions | 372*280*226 mm³ |

| Net Weight | 2.5 kg | |

| Housing Material | ABS/PC | |

| Printing | Filament Supported | PLA, PETG, ABS, ASA, PET, PA, PC, PVA (dried), BVOH (dried), PP, POM, HIPS, Bambu PLA-CF/PAHT-CF/PETG-CF/Support for PLA/PETG, and TPU for AMS |

| Filament Not Supported | TPE, generic TPU, PVA (damp), BVOH (damp),Bambu PET-CF/TPU 95A, and other filament that contains carbon fiber or glass fiber | |

| Filament Diameter | 1.75 mm | |

| Spool Dimension | Width: 50 mm-68 mm | |

| Diameter: 197 mm-202 mm | ||

| RFID Identification | Supported | |

| Drying | Highest Temperature | 65 °C |

| Filament Supported | PLA, PETG, Support for PLA/PETG, ABS*, ASA*, PET*, PA*, PC*, PVA*, BVOH *, PP, POM*, HIPS*, Bambu PLA-CF*/ PAHT-CF*/ PETG-CF*, and TPU for AMS* | |

| Active Moisture Discharge | Supported | |

| Sealed Storage | Supported | |

| Temperature and Humidity Detection and Maintenance | Supported. Real-time temperature and humidity can be displayed on the screen, Bambu Studio, and Bambu Handy. | |

| Power | Input | 24 V 4 A |

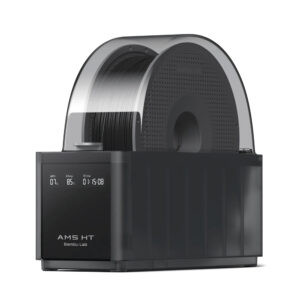

| * Filaments marked with * require a higher drying temperature. The AMS 2 Pro cannot dry them completely. If you want better drying performance for these filaments, we recommend purchasing an AMS HT. | ||

193 IN STOCK

This product has multiple variants. The options may be chosen on the product page

7 IN STOCK

This product has multiple variants. The options may be chosen on the product page

OUT OF STOCK, PRE-ORDER NOW

REQUEST A QUOTE

OUT OF STOCK, PRE-ORDER NOW

2 IN STOCK